PERFECT SOLUTIONS FOR INDUSTRY

Single Entry Water Jet Condenser/ Jet Vaccum Systems

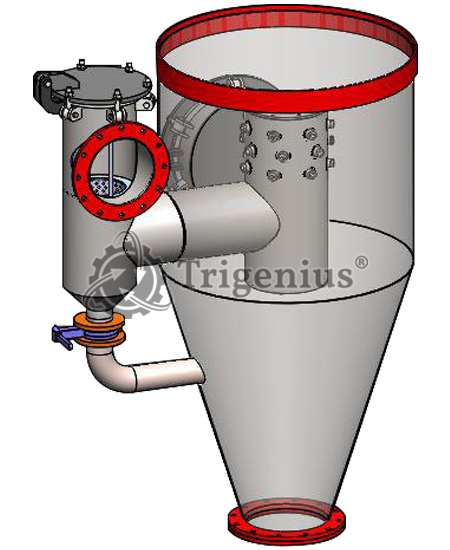

EES Condensers are designed after complete analysis of operating conditions to optimum safety margins and minimum energy losses. Each Condenser operates with close condensing approach and generate initial vacuum rapidly. It maintains good condensing efficiency and non-condensable gas evacuation rate to keep the vacuum and pan temperature at desirable level.

The Condensers are designed for easy and quick maintenance. The Strainer, Spray & Jet Nozzles can be opened for inspection & cleaning very quickly. Stiffing ring without welding shall be provided to give extra strength to the Condenser. Hinge type Manhole and Strainer Dummy further eases the upkeep of the Condensers. Use of corrosion resistant material ensures that Condenser remains unaffected by all kinds of acidic or basic environment.