PERFECT SOLUTIONS FOR ANY INDUSTRIALS

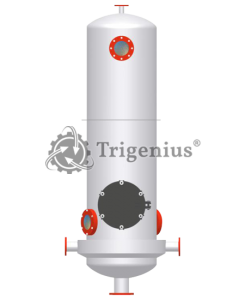

Direct Contact Molasses Conditioner

TEPL EES Direct Contact Molasses Conditioner simple in design, having no moving parts. Heating is continuous& fast. Inspection and routine maintenance are greatly facilitated by conveniently placed access ports. Because of high heating efficiency, a relatively small, lightweight size can be used to deliver a large supply of heated liquid. Heat transfer in direct contact heaters is better than shell and tube heaters because heat transfer resistances like film, fouling, and wall, are not present. Since heat transfer is more effective coinpal, a small direct contact heater can be used thereby minimizing cost. Maintenance is low when compared with costly shut-downs needed to clean tube bundles that act like strainers, when tube pitch is sacrificed for surface area in shell and tube heat exchangers.